Extrusion process in food technology

The principle of extrusion is relatively simple. It yields a myriad of possible shapes and forms. Our earliest exposure to extrusion was probably when we first forced modeling clay through a toy press. The shape or profile of the clay is resultant of the opening shape it was forced through.

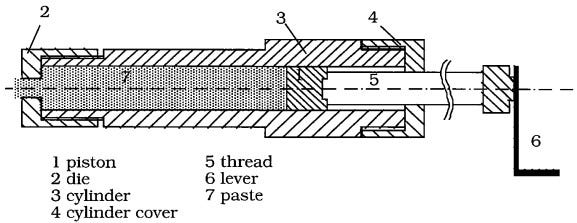

Extrusion cooking is the process of forcing a material to flow under a variety of conditions through a shaped hole (die) at a certain rate to achieve various desirable products. There are three major types of extruders used in food industry: (1) piston extruder, (2) roller-type extruder, and (3) screw extruders. Screw extruders consist of single, twin or multiple screws rotating inside a barrel.

Extrusion processing has been an important food process in the manufacture of pasta, cereals, snacks, pet foods (dry and semi-moist), and textured vegetable protein (TVP). Preground and conditioned ingredients enter the screw where they are conveyed, mixed, and heated by a variety of processes. Product exits the extruder usually changes texture due to the mixing, shearing, and heating process inside the barrel. In many applications, high temperature and pressure and short time process minimize losses in vitamins and amino acids. Color, flavor, and product shape and texture are also affected by the extrusion process.

Textured vegetable proteins (TVP) are products that have been transformed from a flour-type material into one which has a meat-like texture. The resulting TVP possess chewiness, fibrous characteristics and structural integrity that could withstand the eventual preparation for consumption process.

Soy proteins are the most commonly used base materials for TVP. Corn, wheat, peanut and other similar proteins could also be texturised. Soy flour (50% protein) or soy protein concentrate (70% protein) are commonly used as the starting material for making TVP through extrusion process. Post-extrusion, the output is semi-solid and retains moisture. This post-extrusion product could then undergo further marination and coating process, or be passed directly into a dryer to create a dry TVP.

A plant-based meat producer may choose either wet or dry TVP to produce a whole muscle meat product which displays a fibrous texture analogous to a striated muscle, like chicken breast. Or they may choose to produce a restructured meat products, like a burger patty or sausages. Either way, TVP is the main ingredients and additional macronutrients (carbs, fats, proteins), micronutrients (vitamins and minerals), flavors (salt, sugar, spices, additives), and more “functional additives” to impart the final product with certain texture, consistency, and shelf life.